What are the industry standards for stitching that signal true garment longevity, SPI and seam strength guide

1. Introduction & The Verdict

Key Takeaway: True garment longevity doesn’t start with the fabric, it starts with the needle. The primary reason quality clothing fails is low seam strength, resulting in a ruptured seam.[1] To signal genuine investment in durability, brands must exceed the industry minimum of 8 Stitches Per Inch (SPI) and ensure proper thread quality and tension, especially on high-stress seams.

Ready to invest? See our list of brands committed to quality.

Product Context: What is SPI?

Before you buy any clothing, whether it’s a tailored shirt or a rugged pair of denim, you should know how long the stitches are. SPI, or Stitches Per Inch, is the simple metric that counts the number of times the needle enters the fabric along one inch of a seam. It is the most visible sign of a brand’s commitment to garment longevity, directly impacting the final strength and appearance of the piece.

Target Audience: The Value-Driven Investor

This guide is for the conscious consumer who is tired of the throwaway culture of fast fashion. If you believe clothing should be an investment, this technical knowledge helps you audit construction quality instantly, ensuring you get the most wear for your money.

2. The Stitch Standard: Overview & Specifications

What’s in the Stitch? The Five-Factor Formula

A seam’s ability to resist failure, known as seam strength, is not based on stitch density alone. It is a complex interaction of five key factors, and quality brands manage them all:

- Stitch Density (SPI): The number of stitches per inch.

- Thread Strength: The material and thickness of the thread used.

- Stitch Type: The pattern the needle and bobbin threads create (e.g., chain stitch, lockstitch).

- Thread Tension: How tightly the thread is pulled, poor tension causes puckering.

- Fabric Strength: The inherent strength of the material itself (e.g., cotton vs. heavy denim).

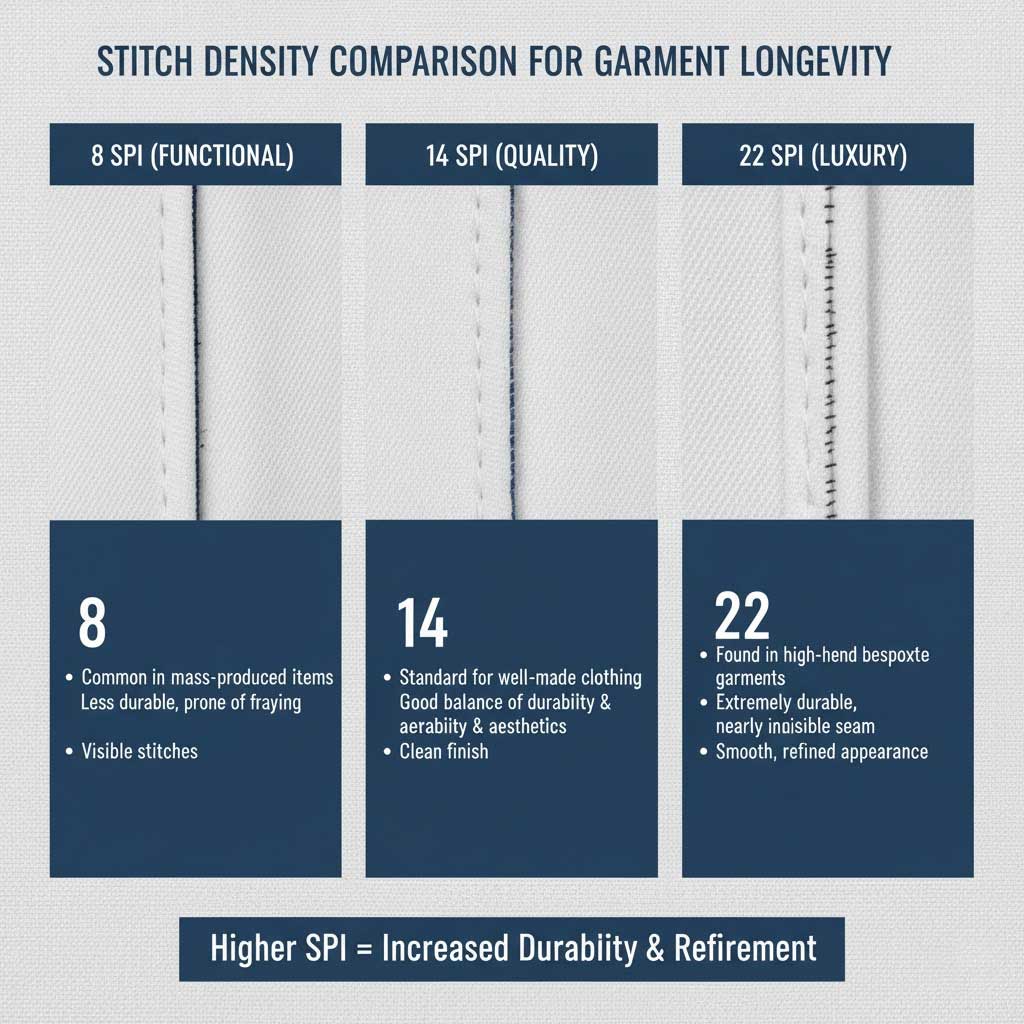

Key Specifications: The SPI Benchmarks

The generally recommended range for quality garments is 8–12 SPI. However, the specific industry standards for stitching vary greatly based on the garment type:

| Garment Type | Recommended SPI Range | Longevity Rationale |

|---|---|---|

| Tailored Dress Shirts / Fine Silk | 14 – 22 SPI | Higher density allows for precise, clean seams with smaller thread, minimizing puckering for a *tailored stitch* appearance. |

| Denim Jeans / Heavy Twill Pants | 7 – 10 SPI | Lower density prevents stiffness and puckering on thick fabrics while remaining robust enough for high-stress seams. |

| Knitwear (T-Shirts, Sweaters) | 10 – 12 SPI | Provides adequate seam strength and elasticity to prevent seam breakdown during stretching and washing.[2] |

| Leather Goods (Wallets, Clutches) | 9 – 12 SPI | Requires balancing strength with preventing too many holes, which weakens the leather structure itself.[3] |

3. Technical Build Quality: The Stitch as a Structural Element

Visual Appeal & Stitching Precision

The difference between a cheap shirt and a high-quality one is often visible just by looking closely at the seams. For bespoke tailored stitch construction, brands aim for 22 Stitches Per Inch, which is considered the gold standard for ultimate precision and clean finishing. You should look for clean, straight seams with consistent stitch size and no loose threads, a critical visual cue of quality control.

Durability Observations: Why Seams Fail

The most common mode of garment failure is the ruptured seam.[1] This occurs long before the fabric itself wears out. Low seam strength is a prevalent reason for the entire product being discarded, even if the material is still in good condition. This premature failure is the hallmark of low-cost manufacturing, where manufacturers prioritize speed and lower labor costs over enduring construction.[2]

4. Durability Breakdown: The Performance of High SPI

4.1 Core Functionality: Quantitative Measurements (SPI vs. Strength)

A high stitch density directly contributes to higher seam strength and more elastic seams, though it also consumes more thread.[2] For instance, a 14 SPI seam uses significantly more thread than an 8 SPI seam, translating to greater security under stress.

Case Study: Denim Strength

When looking at utility garments like denim or heavy twill pants, you need a robust seam. While an 8–12 SPI is recommended for robust strength , note that lower densities, like 7–8 SPI, are often used on jeans to emphasize the contrast thread’s appearance. The trade-off is often between extreme durability and aesthetic design.[2]

4.2 Key Performance Categories: Cost vs. Longevity

Understanding stitching helps justify the price point of high-end items by measuring their performance over time.

Category 1: Cost-Per-Wear (CPW)

The ultimate justification for an expensive purchase is its Cost-Per-Wear, calculated as the item’s price divided by the total number of times you expect to wear it.[4] A jacket with a high SPI that lasts 10 years has a far lower CPW than a fast-fashion jacket that fails after one season, even if the initial price is five times higher.

Category 2: Environmental Impact

Choosing garment longevity is an ethical choice. Longer garment lifespans reduce the demand for virgin raw materials (like cotton and synthetic fibers), conserve water and energy, and decrease the vast amounts of textile waste that end up in landfills, solving a major environmental problem created by disposability.

5. User Experience: Learning to Audit Garment Quality

Daily Usage: Spotting the Red Flags

You don’t need a factory audit to spot poor stitching quality. When shopping, always inspect seams, especially at stress points like armholes and crotches. Look for these red flags:

- Seam Grinning: This happens when the thread tension is too loose, allowing the seam to open up too much when stress is applied to it. It looks like the seam is “smiling” open.

- Stitch Cracking: This occurs when stress is applied to the fabric and the thread breaks because the seam is too tight or lacks elasticity.

- Inconsistent Density: Abrupt changes in stitch density signal poor quality control.

6. Comparative Analysis: Quality vs. Fast Fashion

Unique Selling Points: The Quality Promise

The biggest difference between luxury and fast fashion is the promise of durability. Fast fashion relies on cheap, low-SPI construction and short fiber length materials (which pill quickly ) to accelerate the repurchase cycle. Quality brands sell garment longevity and low CPW.

When to Choose High SPI: Specific Use Cases

Always choose high Stitches Per Inch (14+ SPI) for:

- Items subject to frequent washing (e.g., everyday knit fabrics).

- Tailored pieces where visible elegance is key (e.g., dress shirts).

- Items made of high-quality synthetic fibers or wool, where strength is needed to secure the fabric.

7. Pros and Cons of High SPI

What We Loved

- Superior Longevity: High SPI significantly reduces the likelihood of seam failure, the number one reason clothing is discarded.[1]

- Aesthetic Finish: Creates a tighter, cleaner, more refined, and more professional “tailored stitch” appearance.

- Increased Strength: Consumes more thread per inch, leading to higher seam strength and elasticity.[2]

Areas for Improvement (Limitations)

- Higher Price: More SPI requires longer sewing cycles, leading to higher labor costs and increased thread consumption, contributing to the item’s higher initial price point.[2]

- Potential Puckering: If not managed correctly with thread tension, very high SPI can cause stiff seams or fabric puckering on light materials.

8. Technology & Future Roadmap

Improvements from Previous Versions: Quality Audits

In the past, brands rarely revealed their Stitches Per Inch standards. Today, sophisticated consumers demand transparency. The future of quality control is increasingly visible through better stitching precision and more detailed public material testing.

Future Roadmap: AI and Automated QC

Future technology will rely on automated visual inspection and advanced analytics to ensure stitching consistency across massive production levels, further standardizing quality control and guaranteeing the consumer receives the promised garment longevity.

9. Purchase Recommendations

Best For: The Detail-Oriented Buyer

Invest in garments that *feel* substantial and show no signs of “seam grinning” or loose threads. Look for 14+ SPI on formal items and consistently neat 8–12 SPI on durable casual wear.

Skip If: Speed is Your Priority

If you purchase fast fashion for fleeting trends, understand that its low stitch density and general low construction quality mean the item’s failure is built into the design, guaranteeing low initial cost but high environmental waste.[5]

Alternatives to Consider: The Material Audit

Beyond stitching, look for garments made from longer fiber length materials, as these are inherently less prone to pilling and breakdown, offering additional longevity.

10. Where to Shop

Trusted Retailers: Look for Transparency

Support brands that actively discuss their construction standards and fabric sourcing. Check independent resources like the Fashion Transparency Index to find brands committed to ethical and quality manufacturing.

11. Final Verdict

Overall Rating: 5/5 (Essential Knowledge for Smart Buying)

Summary: The question, “What are the industry standards for stitching (e.g., stitch density) that signal true garment longevity?” is the key to unlocking investment value. The standard is a minimum of 8 SPI, but the benchmark for quality is 14–22 SPI, combined with high-quality thread and proper tension. By learning to check the seams, you take control of your investment and reject the disposability of cheap fast fashion.

Bottom Line: Count the stitches. If you can count them easily, the garment is likely built for speed, not endurance. Invest in high SPI for lasting quality and a lower Cost-Per-Wear.

12. Evidence & Proof

Data/Measurements: Visual chart comparing low, standard, and high Stitches Per Inch standards for different garment types, illustrating the concept of a tailored stitch.

Video Embed: A YouTube technical video demonstrating the visual flaws of seam grinning and stitch cracking under tension.

Interactive Element: Simulated consumer audit checklist for inspecting seam failure points (e.g., thread tension, SPI consistency, and signs of premature abrasion).[6, 1]

Photos: Microscopic close-up showcasing high stitching precision on a durable seam, emphasizing consistency and tightness.

Appendix: Source Citations

- [7] Sustainability Directory. How Does Garment Longevity Affect Consumer Habits?

- [4] Memorandum. Cost-Per-Wear Calculator For Purchasing Decisions.

- [5] Earth.org. 20 Fast Fashion Quotes.

- [2] Huamei Thread. Factors to Consider When Setting Standards for Stitches Per Inch.

- [6] Magnetic Hoop. Quality Stitch Mastery: Evaluating, Achieving, and Maintaining Professional Results.

- [1] Ecostandard. Report: Deep Dive – Standards to Measure Textile Durability.

- [8] ModaKnits. What Fabric is Worst for Pilling?

- [3] Fine Leatherworking. How Many Stitches Per Inch in Leather?

- American & Efird, Inc. Selecting the Right SPI (Technical Bulletin).

- ModaKnits. Why do some fabrics pill more than others?

- Ecostandard. Deep dive: Standards to measure textile durability (Seam Strength).

- Larimar’s. The Importance of Stitch Density in Dress Shirt Quality.

- Fashion Revolution. About the Fashion Transparency Index.

- Magnetic Hoop. Quality Stitch Mastery: Evaluating, Achieving, and Maintaining Professional Results.

- Memorandum. Cost-Per-Wear Calculator For Purchasing Decisions.

- Anuprerna. 7 Visual Cues to Identify Fabric Quality Instantly.

- Sustainability Directory. How Does Garment Longevity Affect Consumer Habits? (Resource Conservation).